![]()

![]()

Contact us

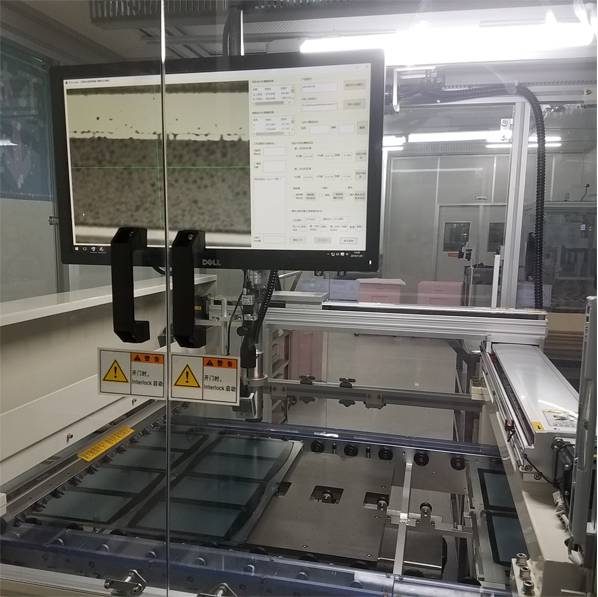

The main function of the ASC-G34SA-A automatic optical printer is to spray a QR code on glass or ink.

The working steps are:

1. Automatic feeding and docking of the printing machine from the previous process;

2. The waiting station that flows to the automatic optical alignment inkjet printer;

3. Wait for the glass of the station to flow to the coding station;

4. The coding station platform is jacked up for mechanical pre-alignment;

5. After the pre-alignment is completed, the CCD automatic visual alignment is performed;

6. After the visual alignment is completed, the code is printed 7. After the code is completed, it flows out to the downstream process.

(1) Alignment mode: mechanical auxiliary alignment + CCD automatic alignment

(2) Product flow direction: facing the operation surface, from right to left

(3) In addition to static electricity function: (inlet + outlet) with ion wind bar

(4) Touch screen operation.

(5) Manual mode can operate all parts separately, which is convenient for machine adjustment.

(6) Vacuum pressure detection alarm.

(7) With sound and light alarm function.

(8) Save the alarm record and check it at any time.

(9) ≥100 sets of recipes can be stored.

| Product Line Name | 34'' automatic ink-jet printing machine |

|---|---|

| Capacity (beat) | ≤40S (calculated in 10 units) |

| Product size range | 550*650mm |

| Overall Dimensions |

Overall line length: 1600 mm Overall line width: 1180 mm Overall line height: 2350 mm |

| Overall Line Weight | 800Kg |

| Air Source |

Pressure: 0.5-0.8 Mpa Air consumption: > 200 L/min |

| Power Supply | Single-phase 220 VAC/50 Hz |

| Rated Power | 3KW |

| Vacuum Source | Vacuum pumping speed ≥ 100 L/min; negative pressure 0 to -100 kPa |