![]()

![]()

Contact us

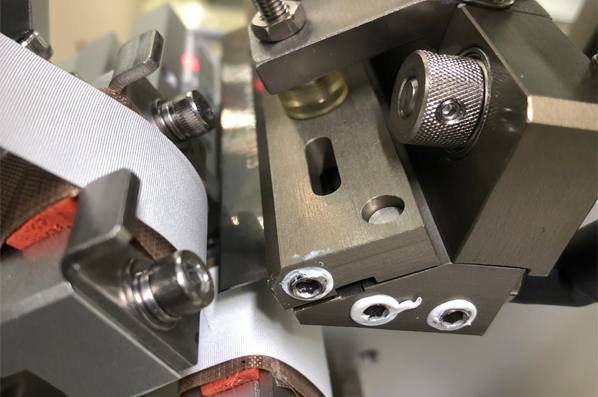

It is applied to TN black-and-white and small-sized LCDs. The mechanical alignment method is used.

The 1-5'' automatic polarizer laminating machine mainly consists of a tray/cartridge feeding machine and a polarizer laminating machine. The automatic polarizer laminating machine is designed to automatically mount various polarizers on substrates. Glass is cleaned with a scraper. No manual operation is required halfway. This production line automatically finishes the entire process of LCD glass cleaning and polarizer laminating.

(1) Online production reduces defects caused by intermediate links;

(2) The automation is high and the efficiency and yield are improved greatly;

(3) Adhesive substances and organic matters on the LCD mirror surface such as Glue particle/glue trace/glass powder can be cleaned;

(4) The cleaning part uses a frictionless magnetic wheel for conveyance to avoid dust generation and glass pollution. The servo motor cooperates with the synchronous belt to achieve accurate conveyance;

(5) Halfway secondary pollution on glass is reduced, thus guaranteeing the laminating cleanliness better;

(6) Glass cleaning and polarizing laminating are finished at a time, thus reducing manual operation;

(7) High intelligence. The commissioning of the complete machine is finished in the touch screen and the commissioning parameters are digitized;

(8) Glass formulas of multiple specifications can be saved and the line changeover speed is fast;

(9) It can be automatically connected to various equipment in the industry such as COGs, FOGs and feeding machines.

| Product Line Name | 1-5'' automatic cleaning and laminating production line |

|---|---|

| Capacity | 3.5s/pcs (Purely mechanical cycle) |

| Glass Requirements | Max: 5'' (Y-axis direction: 70 * X-axis direction: 116) mm Min: 1'' (Y-axis direction: 15 * X-axis direction: 20) mm LCD thickness: 0.2–1.1 mm |

| Polarizer Requirements | Max: 5'' (Y-axis direction: 70 * X-axis direction: 116) mm Min: 1'' (Y-axis direction: 15 * X-axis direction: 20) mm POL thickness ≥ 0.15 mm (Protective film excluded) |

|

Polarizer laminating precision (Mechanical alignment) | X-axis direction: ±0.15 mm (Product factors excluded) Y-axis direction: ±0.15 mm (Product factors excluded) |

| Overall Dimensions | Overall line length: 5,600 mm (Discharge belt line included) Overall line width: 1,200 mm Overall line height: 2,300 mm (Tricolour light height included) |

| Overall Line Weight | 1500Kg |

| Air Source | Pressure: 0.4-0.7 Mpa Air consumption: About 3,000 L/min |

| Power Supply | Laminating part: Three-phase 380 VAC; |

| Rated Power | 4KW |

| Vacuum Source | Vacuum pumping speed ≥ 300 L/min; negative pressure 0 to -100 kPa (Vacuum pump) |